Deep Dive Into Delta House

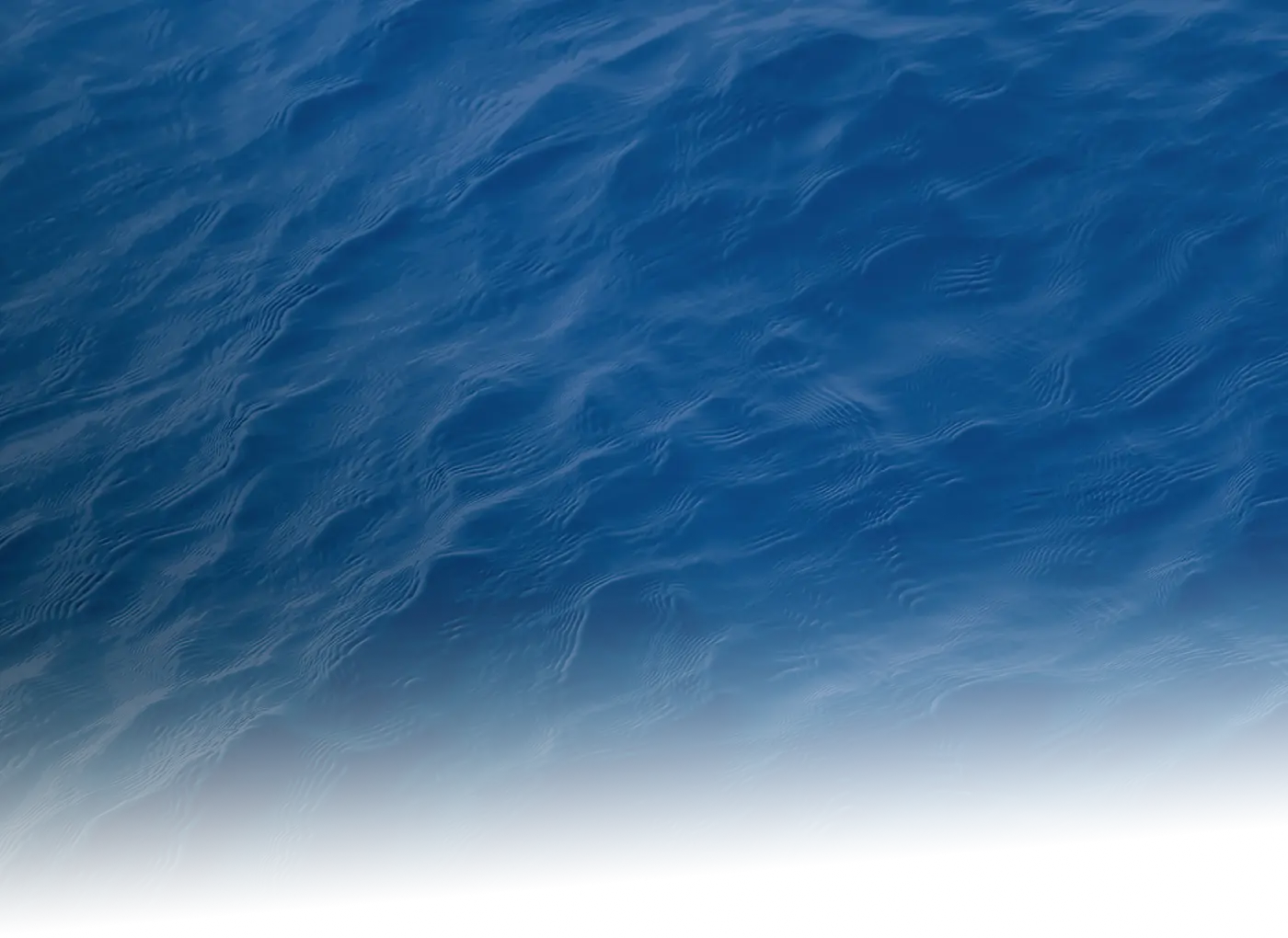

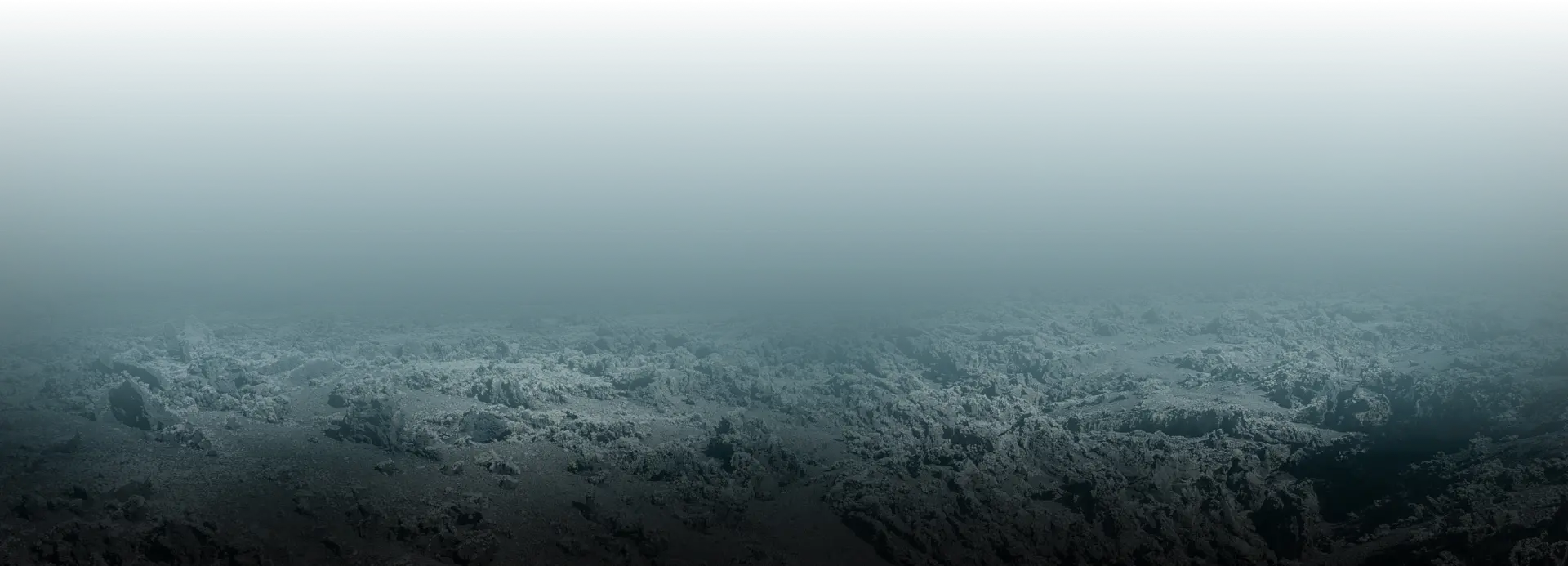

Delta House (MC 254 ”A”) has multiple remote subsea fields tied back: Marmalard (MC 300), SOB2 (MC 431), among others. The location and water depth of the subsea fields (>6500ft) and FPS (>4500ft), presented a unique challenge to field routing. Working hand in hand with LLOG management and flow assurance engineers, the concept of dual, insulated, piggable flowlines connected to mid and end-of-line manifolds was selected.

- Client: LLOG

- Location: Mississippi Canyon 254 “A”

- Water depth:~4,500'

- Overview: New FPU, 10k rated, 2ea 8" Flowlines, 4ea 6" Infield Flowlines, 4 Infield Umbilical, 12 ¾" Oil Export and 16" Gas Export pipelines.

- Gas throughput capacity: 200 MMcf/d

- Oil throughput capacity: 80,000 BOPD

- Flowline size: 6" and 8"

- Length: 30,000' to 70,000'

Heralded as one of the most efficient production systems in the Gulf of Mexico

Offshore Magazine, Dec. 8, 2015

Fueling Success Safely and Efficiently

As one of the most efficient in the industry, the Delta House FPS and subsea infrastructure overcame tight deadlines while maintaining budgetary requirements.

$2 Billion

Total project investment of $2 billion for a peak capacity of the facility at 100,000 BOPD

Subsea Controls

Ethernet and fiber optic systems support data from multiphase flowmeters and well sensors

Safety

With a keen eye on HSE, the Delta House project maintained outstanding safety records

Delta House Marks Groundbreaking Achievement

Honored with both the 2017 OTC Distinguished Achievement Award and recognition as one of Offshore Magazine's top 5 projects in 2015.

Delta House, Under Budget and Ahead of Schedule

Pinnacle Engineering coordinated with over fifty vendors and service providers throughout the execution of the Delta House project. Additionally, umbilical and chemical injection system designs are engineered to address early and midlife needs. These systems are also developed to expand for any future discoveries.